Deep Draw Metal Forming - Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process can be called deep drawing.

Deep Draw Metal Forming - In the bulging process a. High volume of production due to high capacity and high speed of the press. Web these other forming methods include: Web a leader in deep draw metal stamping located in hamburg, nj, accurate forming has been a trusted leader in the deep draw metal stamping industry since its establishment in 1955. Accurate forming is itar registered.

High volume of production due to high capacity and high speed of the press. When compared to other metal forming methods, deep drawing has a wide range of applications. The fundamental structure of deep drawn metals. Web one of the main benefits of deep drawn metal forming is low cost of production/operation per part because of: Our rigid process controls ensure the component will perform as required whenever and wherever needed in the most critical of situations. Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process can be called deep drawing. What’s more, deep drawn parts are exceptionally strong due to the extreme amount of compression exerted on the metal during the forming process.

Deep Drawing Of Sheet Metal

Web deep drawing is a special process in sheet metal forming which is capable of forming many metallic parts and structures, and it covers a wide range of applications in packaging, automotive and aerospace industries. Web one of the main benefits of deep drawn metal forming is low cost of production/operation per part because of:.

Metal forming deep drawing of sheet metal

Web these other forming methods include: Our rigid process controls ensure the component will perform as required whenever and wherever needed in the most critical of situations. Web deep drawn stamping is highly versatile and can be used to create complex, detailed components with an exceptional degree of accuracy and repeatability. Web deep drawing is.

Deep Drawing from A to Z MetalForming Magazine Article

Our rigid process controls ensure the component will perform as required whenever and wherever needed in the most critical of situations. The fundamental structure of deep drawn metals. Web ordnance & law enforcement accurate forming produces components for ordnance / law enforcement applications with strict adherence to both domestic and international standards. Material is displaced.

Deep Drawing Of Sheet Metal

Web one of the main benefits of deep drawn metal forming is low cost of production/operation per part because of: Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body. Web deep drawn stamping is highly versatile and can be used to create complex, detailed components with an.

Deep drawing of sheet metal

A round or shaped portion of metal is cut from the drawn part. Our rigid process controls ensure the component will perform as required whenever and wherever needed in the most critical of situations. Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body. When compared to other.

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Accurate forming is itar registered. Web deep drawing is a special process in sheet metal forming which is capable of forming many metallic parts and structures, and it covers a wide range of applications in packaging, automotive and aerospace industries. What’s more, deep drawn parts are exceptionally strong due to the extreme amount of compression.

The Last Guide to Sheet Metal Forming You Will Ever Need

The finish doesn’t require further processing, and secondary operations such as beading, notching, chamfering. Web ordnance & law enforcement accurate forming produces components for ordnance / law enforcement applications with strict adherence to both domestic and international standards. Web deep drawn stamping is highly versatile and can be used to create complex, detailed components with.

Deep drawing Find suppliers, processes & material

Web ordnance & law enforcement accurate forming produces components for ordnance / law enforcement applications with strict adherence to both domestic and international standards. A round or shaped portion of metal is cut from the drawn part. Web a leader in deep draw metal stamping located in hamburg, nj, accurate forming has been a trusted.

Deep Drawing from A to Z MetalForming Magazine Article

Web deep drawing is a special process in sheet metal forming which is capable of forming many metallic parts and structures, and it covers a wide range of applications in packaging, automotive and aerospace industries. High volume of production due to high capacity and high speed of the press. The fundamental structure of deep drawn.

Deep Draw Metal Stamping Getting Started

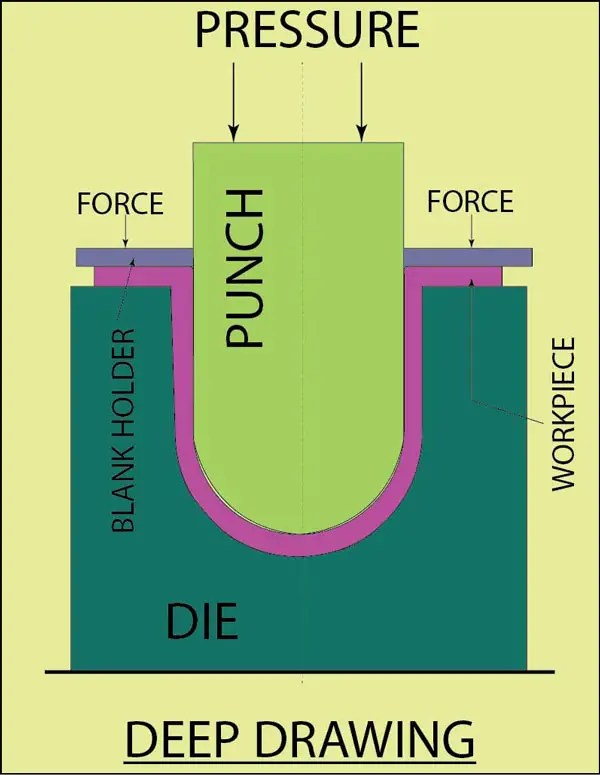

Web according to din 8584, deep drawing is a tensile compression metal forming process, which shapes a sheet metal blank as a hollow body open on the one side or of a projected hollow body to one with a smaller cross section, without intentionally modifying its wall thickness. Our reputation of producing parts with exceptional.

Deep Draw Metal Forming When compared to other metal forming methods, deep drawing has a wide range of applications. The finish doesn’t require further processing, and secondary operations such as beading, notching, chamfering. A round or shaped portion of metal is cut from the drawn part. In the bulging process a. Web these other forming methods include:

Web According To Din 8584, Deep Drawing Is A Tensile Compression Metal Forming Process, Which Shapes A Sheet Metal Blank As A Hollow Body Open On The One Side Or Of A Projected Hollow Body To One With A Smaller Cross Section, Without Intentionally Modifying Its Wall Thickness.

In the bulging process a. Our rigid process controls ensure the component will perform as required whenever and wherever needed in the most critical of situations. Web one of the main benefits of deep drawn metal forming is low cost of production/operation per part because of: Web deep drawn stamping is highly versatile and can be used to create complex, detailed components with an exceptional degree of accuracy and repeatability.

Our Reputation Of Producing Parts With Exceptional Quality Has Been Built On Our Years Of Experience And Expertise.

Specifically, if the depth of the item created is equal to or greater than its radius, then the metal forming process can be called deep drawing. Web ordnance & law enforcement accurate forming produces components for ordnance / law enforcement applications with strict adherence to both domestic and international standards. What’s more, deep drawn parts are exceptionally strong due to the extreme amount of compression exerted on the metal during the forming process. The fundamental structure of deep drawn metals.

Web Deep Drawing Is A Special Process In Sheet Metal Forming Which Is Capable Of Forming Many Metallic Parts And Structures, And It Covers A Wide Range Of Applications In Packaging, Automotive And Aerospace Industries.

The finish doesn’t require further processing, and secondary operations such as beading, notching, chamfering. Web a leader in deep draw metal stamping located in hamburg, nj, accurate forming has been a trusted leader in the deep draw metal stamping industry since its establishment in 1955. Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body. High volume of production due to high capacity and high speed of the press.

Accurate Forming Is Itar Registered.

Web these other forming methods include: When compared to other metal forming methods, deep drawing has a wide range of applications. A round or shaped portion of metal is cut from the drawn part.