Metal Drawing Process - It plays a critical role in determining the shape, size, and features of the drawn part.

Metal Drawing Process - Drawing is a metalworking technique classified under forming, or the deformation of a material by the application of forces to the desired shape without the addition or removal of any of the material. The metal drawing process in manufacturing industry is usually performed cold. Now the rod is made pointed to facilitate the entry into the die. Shearing is a cutting process used to cut sheet metal along a straight line. Web metal drawing metal drawing process.

Many people confuse drawing with stretching. Metal drawing dies, in manufacturing industry, are usually made of cemented carbides or tool steels. Shearing is a cutting process used to cut sheet metal along a straight line. Web applications of metal drawing process metal drawing is utilised to produce wires used in electrical industries made from materials like copper and aluminium. Small diameter rods and tubes are also. Drawing is a metalworking technique classified under forming, or the deformation of a material by the application of forces to the desired shape without the addition or removal of any of the material. Products like paper clips and helical springs are manufactured using the metal drawing process.

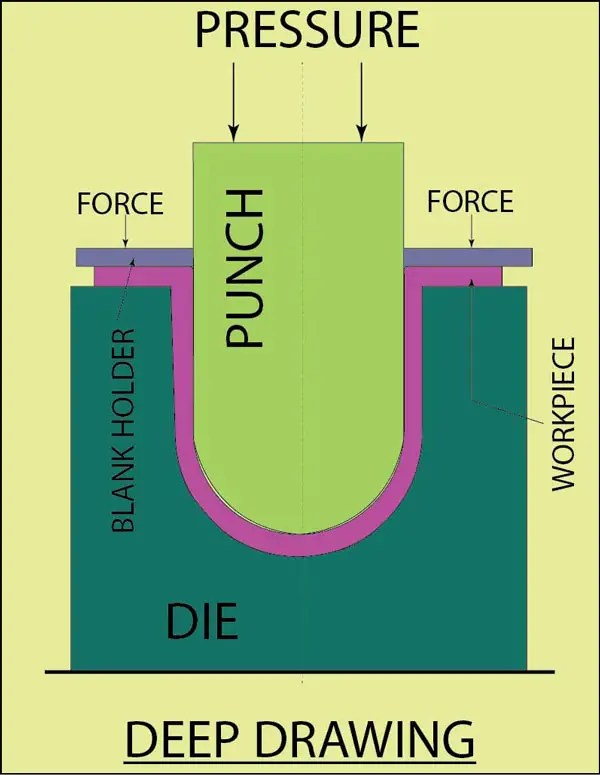

Deep drawing of sheet metal

It plays a critical role in determining the shape, size, and features of the drawn part. The process of deep drawing means that the part must be taller than its minimum width. The punch is the desired shape of the base of the part, once drawn. The surface of the bar or tube is coated.

What Is Deep Drawing ? Working Of Deep Drawing Sheet Metal Processes

Web drawing is a metal forming process in which a product is made by controlling sheet metal flow into a cavity and over a punch. The typical tooling utilized in this process consists of a. Web there are many applications for deep drawing when compared to other metal forming processes. Web drawing can be defined.

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI

Web drawing can be defined as a forming process in which the flow of metal into a cavity or over a post is controlled. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. What are the different types of dies? Drawing is a metalworking technique classified.

Metal Drawing How Metal Drawing Works

This technique is commonly used to produce wires, tubes, and various metal components with precise. The process of drawing metal wires, rods, and bars is a crucial technique in the manufacturing industry. The dust or other scale particle should clean from the rod. Web metal drawing metal drawing process. Many people confuse drawing with stretching..

Metal Forming Basic, Types , Diagram , Classification Learn

The industry uses it extensively. The process of drawing metal wires, rods, and bars is a crucial technique in the manufacturing industry. Metal drawing is a metalworking process by which metal is stretched and formed using tensile force. Small diameter rods and tubes are also. It breathes life into mundane metal sheets, sculpting them into.

Sheet Metal Drawing Process Bornmodernbaby

Now the rod is made pointed to facilitate the entry into the die. The process of deep drawing means that the part must be taller than its minimum width. Renewable energypowder coatingcutting precisioncustom parts It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. Like the similar.

Metal Drawing

Metal drawing is a metalworking process by which metal is stretched and formed using tensile force. The mold for deep drawing is been called deep drawing die. The die cavity matches the punch and is a little wider to allow for its passage, as well as clearance. Stick welding is often used, but other methods.

The Last Guide to Sheet Metal Forming You Will Ever Need

Drawing is a metalworking technique classified under forming, or the deformation of a material by the application of forces to the desired shape without the addition or removal of any of the material. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts.

32 Basic sheet metalworking operations (a) bending, (b) drawing and

Products like paper clips and helical springs are manufactured using the metal drawing process. Web metal drawing metal drawing process. Web deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under.

Metal Drawing

Web metalworking is the process of shaping a metal into a part or component. Web figure 1 ears are the result of varying metal flow patterns that occur during the drawing process. This technique is commonly used to produce wires, tubes, and various metal components with precise. It involves applying tensile forces to the material,.

Metal Drawing Process Web metalworking is the process of shaping a metal into a part or component. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. Web first a hot rolled rod is created by other metal forming processes like forging, extruding, centrifugal casting etc. Metal drawing can result in a metal with a. The industry uses it extensively.

This Technique Is Commonly Used To Produce Wires, Tubes, And Various Metal Components With Precise.

The process is typically performed cold, which is done to ensure accurate tolerances, better grain structure and surface. What are the different types of dies? Metal drawing is a metalworking process by which metal is stretched and formed using tensile force. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products.

Web Metal Drawing Metal Drawing Process.

Web one of the significant advantages of metal drawing is its ability to work with a wide range of metals. It plays a critical role in determining the shape, size, and features of the drawn part. The dust or other scale particle should clean from the rod. The mold for deep drawing is been called deep drawing die.

Renewable Energypowder Coatingcutting Precisioncustom Parts

Web first a hot rolled rod is created by other metal forming processes like forging, extruding, centrifugal casting etc. Web drawing is a metal forming process in which a product is made by controlling sheet metal flow into a cavity and over a punch. Like the similar extrusion process, during which a metal is pushed through a die using a draw punch. Products like paper clips and helical springs are manufactured using the metal drawing process.

Web Metal Drawing Is A Metalworking Process Where A Workpiece Is Pulled Through A Die To Reduce Its Diameter And Increase Its Length.

The surface of the bar or tube is coated with a drawing lubricant such as phosphate or oil to aid cold. Perhaps one of the biggest misconceptions about deep drawing is that the metal is stretched into the part geometry. The metal drawing process in manufacturing industry is usually performed cold. The typical tooling utilized in this process consists of a.